Some of our friends/partner have written a series of articles on why the Trump administration is going to have a (very) hard time moving the needle with manufacturing jobs.

It’s not just that manufacturing jobs have moved to China. There are (at least) three other factors.

- Automation and the rise of robots to do the low-end work will eliminate many jobs entirely.

- What economists call “job density” meaning the number of jobs per entity in a particular industry sector like manufacturing is down, way down, due to increases in productivity per worker.

- A shortage of workers with the right skills.

For these and other reasons, it’s important to focus on resilient jobs, that is jobs that provide a real stepping stone into the middle class. We define resilient jobs as jobs that meet the following criteria:

- take advantage of a local supply chain (at least 50% of the product is made locally)

- pay at least $20/hour

- where workers with different skills are paid more for those skills

- where the employer has some explicit focus on upskilling workers on an ongoing basis.

Here’s a short reading list, for those interested in “getting smart” about these issues.

- The New Good Jobs — City Lab (Anthony Carnevale, Dec 2016)

- What so many people don’t get about the U.S. Working Class — Harvard Business Review (Joan Williams, Nov 2016)

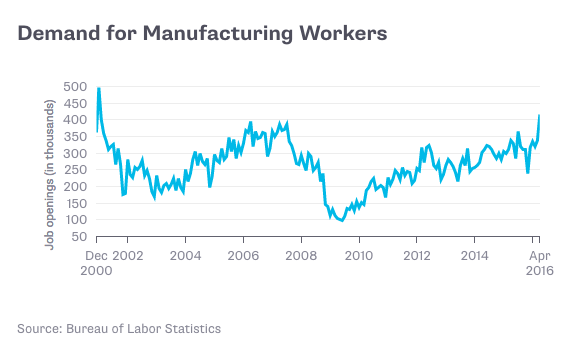

- A single chart everybody needs to look at before Trump’s big fight over bringing back American jobs — Washington Post (Ana Swanson, Nov 2016)

- It won’t be easy to bring back millions of manufacturing jobs — Brookings Institution (Mark Muro, Nov 2016)

- Slogans aside, Donald Trump won’t be able to make manufacturing great again — Washington Post (Philip Bump, Dec 2016)

- The surprising problem with U.S. manufacturing: it’s creating too many jobs — The Atlantic (James Fallows, June 2016)

- Make to Manufacturing Playbook — SF Made (Dec 2016) — while specific to San Francisco, this report showcases what it will take to create the kind of dense ecosystem that Apple has in Shenzen, for example, where it manufactures the iPhone

For a checklist of what you can do locally to encourage manufacturing to flourish, go to http://makercity.com/checklist/